Thermal Energy Storage

Nowadays, the global energy supply is one of the most important concerns for developed countries. Trends in energy supply and use are economically, environmentally and socially unsustainable. Both population growth and industrial development have led to a continuous increase of energy consumption. For several decades, the implementation of renewable energy that helps supply the large energy demand has contributed towards the reduction in the consumption of conventional polluting energy. Energy Storage has become a key facilitator for energy transition into clean energies. Energy storage technologies can provide energy security, fight climate change, and improve the value of current or future energy systems. In addition, energy storage has a main role in energy efficiency in buildings and industrial energy intensive processes. Thermal Energy Storage (TES) is a key enable technology, as it allows to stock thermal energy that can be further used for heating and cooling applications and power generation.

From the TES material perspective, there are three different ways for storing heat or cold for later use. They are classified according to the way of storing the heat in sensible, Latent or Thermochemical.

Sensible heat storage

In sensible heat TES materials, the heat energy is stored according to their specific heat capacity (Cp). Temperature increases as the system stores energy. Current commercial Concentrating Solar Power (CSP) plants use sensible heat storage for storing energy by using molten salts and thermal oils. Sensible heat storage is considered a mature technology. However, there are plenty of novel applications being developed.

Latent heat storage

Latent heat storage works storing the energy during a phase change (usually solid-solid or solid-liquid). The temperature is stable during the phase change and the energy storage density is higher compared to the sensible storage. Materials used for lantent heat storage are often called Phase Change Materials (PCM). PCM implementation and development depends largely on the application temperature range. Low temperature applications in building, food industry, cooling for medications or cooling for medical transplants are almost fully developed but their introduction to the market is slow. Nevertheless, use of PCM in high power systems are under research and development.

Thermochemical heat storage

Thermochemical storage is achieved by reversible chemical reactions that can absorb or release heat associated to the reaction enthalpy. These reactions depend mostly on the pressure and temperature, as most of the reactions studied are solid-gas reactions. Energy density is higher compared with latent and sensible heat storage. Nevertheless, thermochemical storage is under early development and there is almost no commercial application. High costs and complexity as well as materials in the reactor design are the main aspects being developed in this technology.

Our Research in TES

Al three TES techonologies are being studied and developed in DIOPMA.

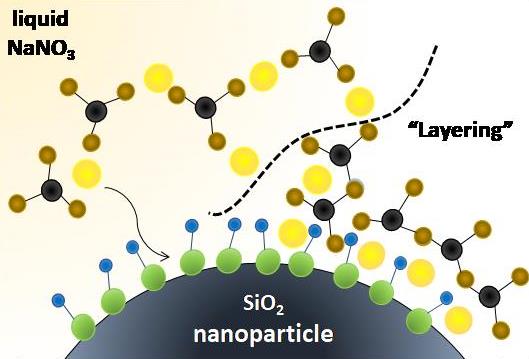

Molten salts properties and enchancement is being carried out as well as corrosion materials compatibility is being studied. Also, use of nanofluids for enchancing of sensible TES materiales are being developed. Nanofluids for TES research in DIOPMA is based on synthetize and characterize this kind of novel fluids to be used as a thermal energy storage medium or heat transfer. The nanofluids under study in our labs range from organic material such as paraffin’s to inorganic materials such as molten salts. The focus of the investigation is based in understand the thermo-physical properties of nanofluids and their stability to develop a theoretical framework. Therefore, with the purpose of design nanofluids with specific properties and scale up to industrial application.

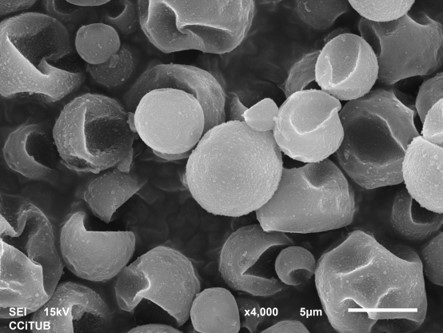

In order to increase temperature range for heat storage solid particle materials are being studied. These are typically Ceramic materials that can have service temperatures above 1000 °C. Materials durability and compatibility are being evaluated. In particular Solid Particle for CSP are of particular interest to DIOPMA. The main aim is to overcome the temperature and stability drawbacks, since solid particles are used as both TES and Heat Transfer Fluid (HTF) material. The solid particle TES system has high performance due to the high temperature operation, and low cost from the materials perspective. Some of the aspects under study are thermal aging, thermal cycling stability, optial properties, composition characterization, morphological properties, among others.

Current efforts for improving global sustainability had evolved to Circular Economy industrial system development in which material resource are used as long as possible within different economic activities. In order to meet world sustainability goals, TES materials are being studied from a Circular Economy perspective. Use of byproducts, industrial waste, or materials that can be of high value and the end of its first life cycle as TES materials are under study. The main objective is to use materials that can have as many life cycles as posible by recyling, reuse, downcylce, etc.

Networks

DIOPMA Centre is a member of the Spanish network fo thermal energy storage. This network was created to enhance synergistic activities between different Spanish research groups in TES with the objective to improve and consolidate Spanish research at an international level. It is expected that the results of the research work carried out within this framework contribute to provide solutions in the industrial and technological field and may give society greater visibility of the different applications in which the TES is an advantage.

Recent projects

- Decarbonization strategies integrating thermal energy storage

- CSPplus

- Network R+D+I Energy for Society (XRE4S)

- MATCE: Methodology for analysis of thermal energy storage technologies towards a circular economy

- INPATH-TES

Recent Publications

- Thermal stability and durability of solar salt-based nanofluids in concentrated solar power thermal energy storage: An approach from the effect of diverse metal alloys corrosion

- Designing thermal regulation materials: Investigating alkylamine length in polymorphic layered hybrid organic-inorganic perovskites

- Synthesis optimisation of copper-based layered perovskites as thermal energy storage materials

- A Bibliometric Analysis of Research and Development of Nanofluids

- Using statistical analysis to create a new database of Nanofluids specific heat capacity

PhD dissertations

- Nitrate salt-based nanofluids for thermal energy storage

- Study of solid particle materials as high temperature TES and HTF for CSP

Materials for Energy Research Team